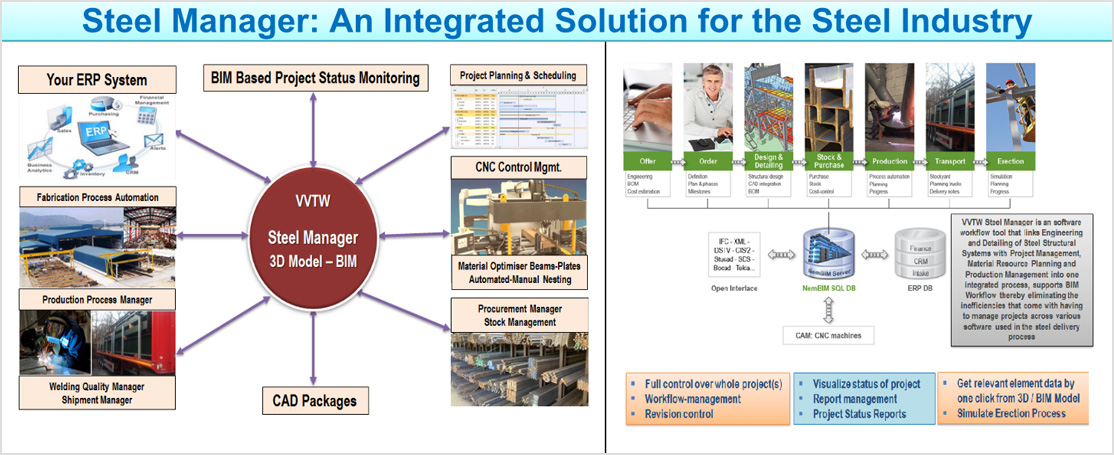

Steel BIM Manager

(3D Model Based Project Management) |

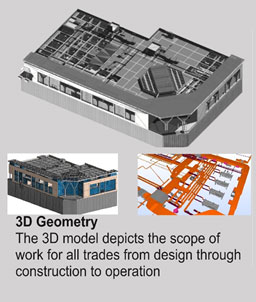

- Complete projects management centralized in one unique platform, retrieving all the data from engineering to visualize all the production information’s on our 3D model

- Project Status reporting supporting BIM process

- Support full traceability throughout project execution life cycle

|

|

Master Scheduler |

- Full planning solution considering all your resources linked to your production

- Opportunity to find optimum way of planning resulting saving time at multiple phases of project execution.

- Registering and improving the process-efficiency

|

|

Production Process Manager |

- Automatizing your complete production operations around your fabrication facilities.

- Automating and organizing the production around the workshop

- Planning with a professional and productive approach

- Automating and organizing the production around the workshop

- LEAN : eliminate no-adding- value-tasks (WASTE) within the process

- Automating beyond CAM and ERP

|

|

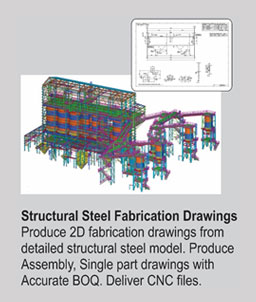

CNC Management |

- Automatic connection of all your CNC machines providing error-free operations

- Centralized CNC management with multiple machines brining needed control over

|

| Material optimizer Beams |

- Save cost by providing the best cutting and offcut management for all your beams / bars

|

| Material optimizer Plates |

- Save cost by providing the best cutting and offcut management for all your Plates

|

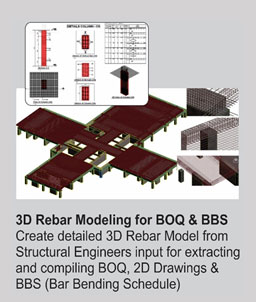

| Stock Manager |

- Stock management for a full traceability of all the materials

- Optimizing and resolving your bottlenecks

- Developing Efficient process

|

| Shipment Manager |

- Full traceability of all your shipments, truck loadings and deliveries

|

| Procurement Manager |

- Procuring you the best purchase information’s -> savings

on material

|

| Quality / Welding Manager |

- Welding information and inspection system for a full traceability of all welding operations

- Use of the CAD-model at the fullest including WIS (Welding Information System)

- Generating & Maintaining Quality

|

|

Management Information |

- Up to date status information with analytical reports and charts

|